Polyimide is a super engineering plastic developed by U.S. company DuPont. It is characterized by extremely high resistance to temperatures of up to 500℃ as well as chemical resistance and mechanical features.

Technical fields

Low Power Consumption

Social infrastructure such as power infrastructure, railways, motor vehicles, and manufacturing industries, is making an accelerating shift to electrification. The devices used in these fields are required to be highly power efficient and highly reliable. HD MicroSystems contributes to society by providing environment-friendly solutions, in addition to our industry-proven conventional materials.

High Performance Computing

Cloud computing, on which the present society is built, is supported by a huge number of logic circuits such as IC/LSI and data storage devices. As the volume of information is increasing exponentially, technologies that can process it in a speedy and safe manner are required. HD MicroSystems contributes to realizing high-speed telecommunications by providing materials that meet customer needs.

High Speed Connectivity

Mobile devices, including smartphones, tablet PCs, and wearables, are interconnected via networks, and information undergoes sophisticated processing in the cloud through the networks. Putting these technologies into practice requires high speed and small, energy-saving semiconductor devices. HD MicroSystems provides functional and unique materials to produce such devices, thereby contributing to “smart connectivity.”

Features of Polyimide

Polyimide has exceptionally high heat resistance compared to other resins, making it likely to be the only super engineering plastic that can be liquefied in a high-temperature environment of 200℃ or higher with minimal physical degradation.

It is a tough material that can withstand exposure to chemicals as well as shocks, friction, bending, and torsion.

Also, with a low permittivity of approximately 3.0, it can control its coefficient of thermal expansion (CTE) depending on the substrate materials, thereby finding wide applications including circuit substrates and machine parts.

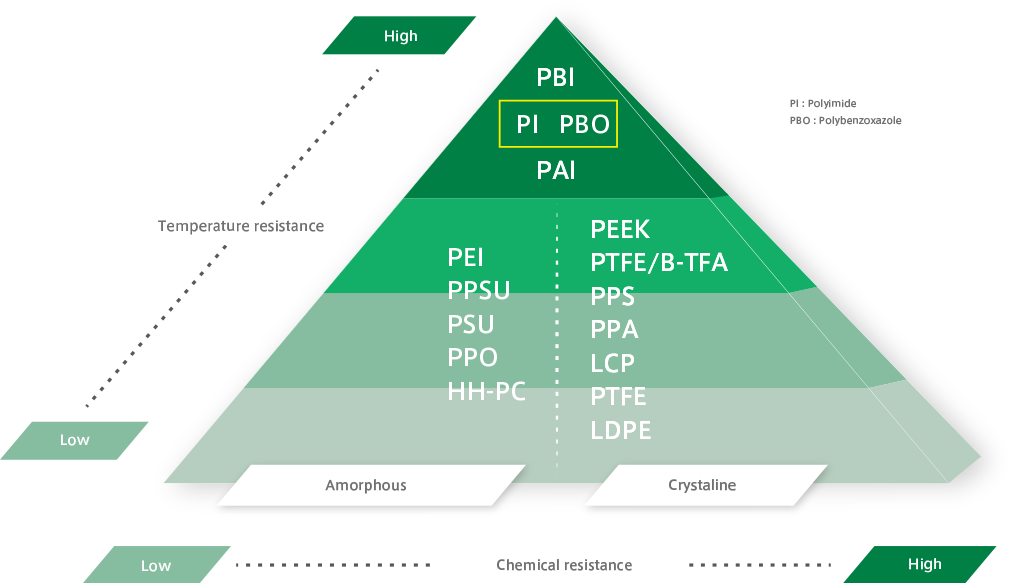

Engineering plastic characteristic diagram

Typical Applications

Stress buffer layer

We provide polyimide coating products that satisfy a wide variety of process conditions and physical property requirements and are environment-friendly to cover the circuit boards of various devices ranging from advanced node devices to industrial high-power devices. Our polyimide film, serving as a stress buffer, is approximately 3 to 10 μm thick and protects wiring and inorganic insulating layers from the stress of mounting work and temperature changes to ensure reliability.

Redistribution layer

In mobile devices, etc., represented by smartphones and wearables, solder or copper bump bonding technology and multi-layer interconnection technology are utilized to increase packaging density. In this application, our products with high resolution and compatibility with dissimilar materials enable smaller devices and higher reliability. In this field, we have been releasing environment-friendly products that are compatible with even devices with structures or characteristics that limit process temperature, thereby contributing to progress in PKG processes.

Temporary adhesive

In recent years, the substrates for 2.xD packages, power devices, etc. have been becoming increasingly thinner, necessitating a way of handling and packaging that will not damage such substrates. With high heat resistance and chemical resistance, our polyimide also finds its use in temporary and permanent adhesives to provide various solutions in these applications.

Features of Polyimide Products from HD Microsystems

High Resolution

We have achieved densification of semiconductor packages by enhancing the resolution of photosensitive polyimide, thus contributing to the further miniaturization of electronic parts.

High Functionality

To satisfy the needs of customers, we are able to rapidly develop highly functional new polyimide products with added value such as in the form of photosensitivity, mechanical properties, and adhesiveness.

High Reliability

We are working on product design that ensures high reliability by performing accelerated tests on customer devices to evaluate the durability required to preclude defects.